Projects

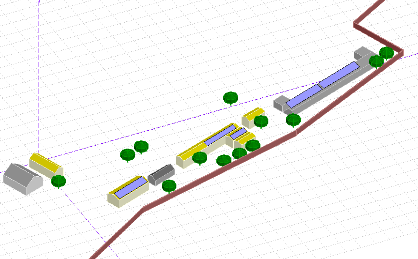

Rural and Peri-Urban Water Supply in Punjab – Phase 1

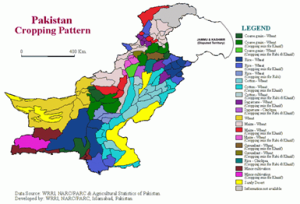

The Government of Punjab developed the ‘Khadim-e-Punjab Saaf Pani Program’ to guarantee safe drinking water supply in rural and peri-urban areas of the province of Punjab. The Program cost about USD 2.8 billion and covered 137 rural tehsils (~ 20,000 villages). To achieve the objectives of the Program, the Punjab Saaf Pani Company (PSPC), an autonomous government-owned company was established. Punjab Saaf Pani Company entrusted the Consultant with the role of the Owner’s Consultant in the first phase of the Program to safeguard PSPC’s interests in executing 14 EPC contracts for design, supply, installation and 5-year O&M contracts for various projects in the water sector.

Services Provided

- Review of Feasibility Studies and preparation of Engineering Design

- Review & Update Feasibility Study and Gap Analysis.

- The feasibility studies included option analysis for determining the most cost effective approach to provide clean drinking water, i.e. cluster, vs stand alone, vs hybrid of the two.

- Review & Update Feasibility Study and Gap Analysis.

- Village level surveys were carried out to ascertain existing water sources in rural Punjab

- ERS measurement campaigns were carried out to identify areas of water availability, followed by developing trial bores for assessing water quality and quantity.

- Planning for Rural Area Drinking Water Supply, which included design of clean drinking water schemes to provide drinking water to 90% of the population within a 1 km radius.

- Preparation of Engineering Design (Hydrology and Hydrogeology Study; Seismic Evaluation; Technical Specifications; Design & Drawing of Civil Structures, Water Wells and Water Treatment; Financing Planning; Preparation of BOQ and Costing; and EIA, Environmental Management Plan)

- Preparation of Bidding Documents (General conditions of contract; Special conditions of contract; Bid and Appendices; Special provisions; Specifications; Bills of Quantities and equipment lists; Drawings; O&M Requirements; etc.)

- Technical assistance in Pre-qualification, Tender Evaluation, Contract Award, Construction Supervision, Final Handing-Over, Start-up Operations, and Economic / financial studies.

- Water samples were collected from each village and populated area to analyze water quality to propose suitable filtration plant along with suitable capacity.

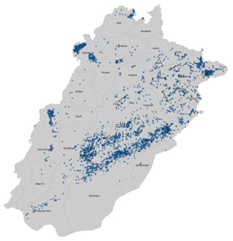

- During Punjab Saaf Pani Project around 17,000 settlements were digitized in 6 assigned tehsils and tribal area of Rajanpur and Dera Ghazi Khan.

- GIS Survey was carried out to estimate distance of proposed plant from existing 11 kV line for provision of electricity to these plants.

- GIS enabled topographic survey of tribal area was carried out to survey pipe line route for elevation profiling so that suitable pump type and capacity should be proposed. Total pipe length was 3,000 km.

- Based on GIS spatial analysis, the client is able to install filtration plants in such a way that clean drinking water was available to almost every citizen within 1 km distance.

- GIS proximity analysis was performed for site suitability analysis to install Tube wells and hand pumps along with filtration plants

Feasibility Study of Integrated ERP Solution – Water and Sanitation Services Peshawar (WSSP)

There is dire need for a system to be emplaced for tackling the water and sanitation information collection and usage challenges. The system is envisaged to enable WSSP monitor its progress, decision making, mapping of resources, maint central data repository, and make better mobilization of its resources through implementation Management Information System (MIS) and Geographical Information System (GIS). The requirements of MIS and GIS for WSSP are as follows,

- Mapping of resources and facilities;

- Identification of information and development of a central repository for information;

- Development of a mechanism to capture, store, and integrate this information;

- Creation of different level of user on the basis of information nee

- Development of WSSP linkages with relevant governmental departments for smooth operations;

- Support the function of “better water and sanitation services for all”; and

- Strengthen governance and assist in decision making.

Services Provided

Activities

The overall goal for implementing new technology not only focuses on the technology itself, but also aims to enhance existing business processes performed by individual departments across the utility. Technology is intended to enhance departmental business processes by: making them more efficient; making them more effective; improving decision-making; providing enhanced customer service to both internal and external customers; improving access to information; and streamlining processes to reduce costs. The intent of this ERP Feasibility Study was to define a future course of action for business process automation and related applications and side systems. The approach utilized for collecting information included interviews with primary process and systems owners, IT staff, and various department users regarding the existing technologies and processes.

Several documents were prepared including: detailed System Requirements Specifications; Stakeholder Analysis & Communication Mechanism; Financial Analysis of ERP Solutions; Financial Analysis of GIS Solution; and a detailed Phase-Wise Implementation Plan.

World Bank ESMAP: Renewable Energy Resource (Biomass) Mapping for Nepal

The Government of Nepal (GoN) endorsed the “Concept Paper on National Energy Crisis Prevention and Electricity Development Decade, 2016” in February 2016 to address both the short term energy crisis as well as lay the basis for long term sustainable development of the sector by developing 200 MW generation capacity (or at the rate of 10% of a total generation capacity in the country) of the national grid connected solar and wind projects in the next 10 years.

In support of GoN’s objectives on solar, the WB has agreed to add a solar measurement campaign to the existing project on Renewable Energy Resource Mapping, which is currently focusing just on wind mapping. The solar measurement data, once the assignment is completed, shall be used to produce a country adapted and validated solar map for Nepal. The assignment includes the planning, commissioning and implementation of a high quality solar measurement campaign at five sites, including regular delivery of bankable solar data over a two year period.

Services Provided

- Visiting the proposed site locations and selecting the optimal location for the measurement equipment

- Procuring and importing high quality measuring equipment for each site, in line with the technical specifications;

- Arranging for site permitting and access

- Commissioning of the sites

- Providing two years of high quality, ‘bankable’ meteorological data relevant for solar resource assessment and project development, including transfer to an ‘open data’ platform for public dissemination

- Ensuring maintenance, security, local cleaning/caretaking, mitigation against extreme weather events2 and corrosion, and a full re-calibration at the end of the measurement period

- Ensuring strong local involvement and capacity building at all stages of the measurement campaign to enable the site and/or equipment to be taken over by an institution or company mandated by the GoN once the contract comes to an end

ADB – Khyber Pakhtunkhwa inclusive Urban Growth Program

Cities Development Initiative for Asia (CDIA), in close cooperation with the ADB, is seeking the assistance of a qualified consultancy firm that can help the Government of KP to strategic city planning within a regional context and identify physical infrastructure investments required to enhance inclusiveness, resilience and competitiveness within the cities of Peshawar, Mardan and Abbottabad and their regional context. Priority should be given to infrastructure investments which stimulate job creation and private sector development.

Services Provided

- Prepare City Development Plans for Peshawar, Mardan and Abbottabad (which will include institutional, financial, economic, climate change analysis and approaches for urban sub-sectors)

- Identify potential priority urban infrastructure investments in these cities and prepare 10-15 year investment plans

- Recommend institutional arrangements for the implementation of the PFS

- Carry out a PFS for the prioritized urban infrastructure investments identified in these cities

- Identify possible sources of financing for the prioritized investments including community financing, NGO support, and PPP options as part of the ADB supported KP Intermediate Cities Investment Improvement Program

- Enhance the capacity of relevant stakeholders to facilitate the sustainable development and management of prioritized urban infrastructure investments.

Policy Review and Advisory on the Promotion of Renewable Energy and Energy Efficiency in Industries in Pakistan

funded by UNIDO

UNIDO, upon request of the Government of Pakistan, developed a project in Pakistan to promote market based adoption of Renewable Energy and Energy Efficiency and services in industries in Pakistan. The project, titled “Sustainable Energy Initiative for Industries in Pakistan”, seeks to promote the adoption of renewable energy and energy efficiency technologies and services in industries. The ultimate goal of project is to avoid greenhouse gas (GHG) emissions by developing and promoting a market environment that will stimulate investments in renewable energy and energy efficiency which, in turn, will help drive economic growth, support industrial development in Pakistan. The project consists of three components:

- Develop the policy and regulatory framework on use of EE and RE in industry

- Promoting RE and EE investments in industry

- Create platform for promoting investment and sustainability

The assignment “Policy Review and Advisory on the Promotion of Renewable Energy and Energy Efficiency in Industries in Pakistan” to component 1 of the project.

Services Provided

- Literature Review of Local and International RE and EE Policy Frameworks

- Consultations with Project Partners and Key Stakeholders

- Preparation of final drafts of RE and EE policy recommendations

- Presentation of final drafts of RE and EE policy recommendations, including implementation roadmaps, in a national level workshop

- Preparation of Final Review and Recommendation Policy Document on RE and EE for Industrial sector

ABC Installation at PESCO funded by USAID

Under the USAID – financed Power Distribution Program (PDP), PITCO is a major subcontractor to International Resources Group, a US company, tasked to improve the financial, commercial and technical standing of the nine Government owned electric power distribution companies (DISCOs). The total employee strength of the DISCOs is about 124,000. PDP, a $230 million program. PITCO provided its key professionals in different areas to meet the PDP requirements.

PITCO has been the main resource for conducting Cost of Service Study for tariff determination. Since, tariffs are not calculated based on actual COS and result in low revenues & the need for subsidies, a COS study for allocation of costs to various categories of customers served is an essential prerequisite to establish tariff rates that are fully cost reflective. The main objective of the study is to assist DISCOs in improving their performance and efficiency by improving their capacity to determine appropriate tariffs for consumers.

There are two components of the project,

Component I: Cost of Service & Tariff Design

- Liaison & coordination with DISCOs for data collection and data analysis;

- Development of customized Cost of Service (CoS) Mode to allow DISCOs to calculate cost reflective tariffs

- Guidance and hands on support for implementation of CoS Model for each DISCO

- Revenue Requirement Estimation involving analysis of financial statements, budgets, capital expansion plans, sales, and demand and load data projections

- Selection of appropriate methodology to allocate costs to different customer categories

- Structuring Tariff Design, based on justifiability, transparency, and simplicity, to give price signals to consumers for efficient utilization of electricity

- Installation of AMR meters at all feeders across Model DISCO (also at a sample of transformers and consumers, at each DISCO during the Cost of Service Study for that particular DISCO) to improve the quality of input data for Cost of Service study

- Training sessions for DISCO & NEPRA professionals on various areas but not limited to CoS, Performance Benchmarking, Strategic Planning, Balance Score Card development and implementation

- Preparation of user manuals and Close-Out Reports for all DISCOs.

Component II: Assistance to NEPRA

- Organizational Restructuring of NEPRA for effectively regulating the entire Pakistan power sector

- Improvement in regulatory guidance for DISCOs regarding power acquisition

- Review of electricity sector market framework internationally and development of vision of the competitive market structure

- Review of Tariff rules and regulations and recommend modifications and more efficient approaches for Tariff determination

- Assessment of existing Information Technology infrastructure (hardware/software) and identification of better alternatives and procurement as well as relevant training for sustainable use.

- Assessment and establishment of relationship between NEPRA and international regulatory bodies (regional or countries with similar conditions) and facilitation in out/in-country training and information exchange.

- Identification of solutions and recommend changes in Regulatory Laws for introduction of international best practices

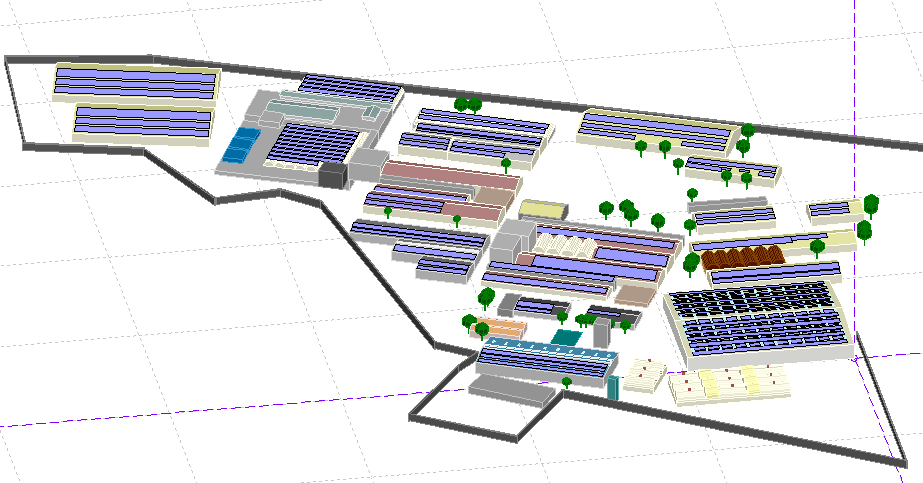

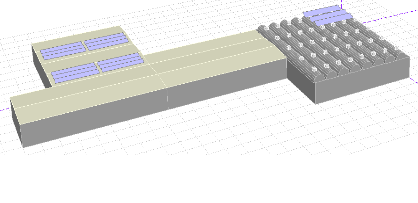

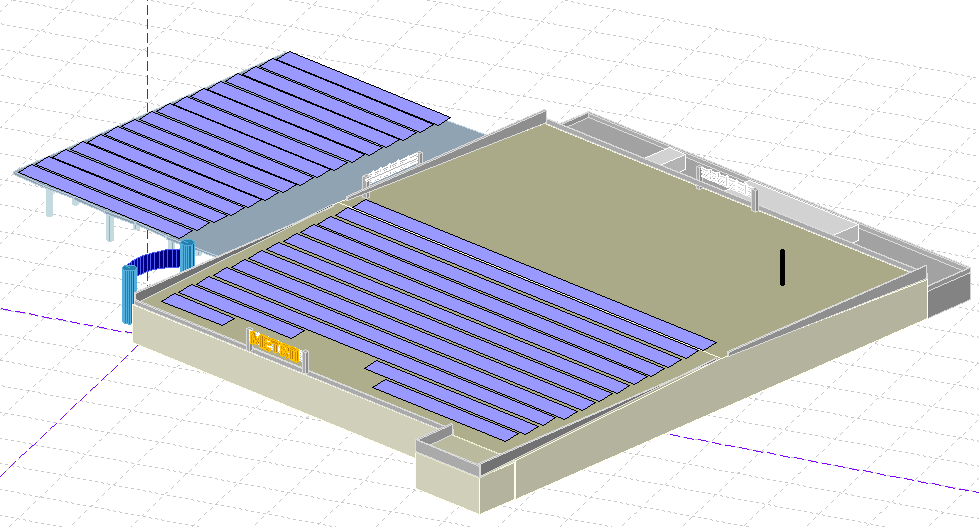

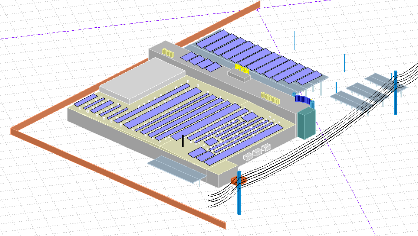

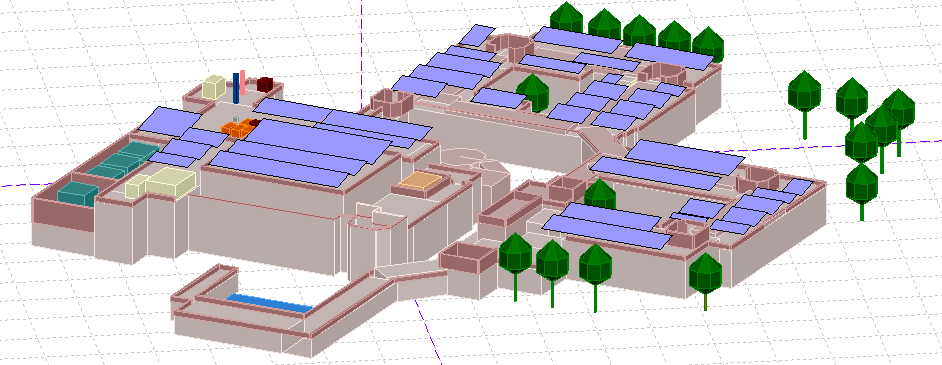

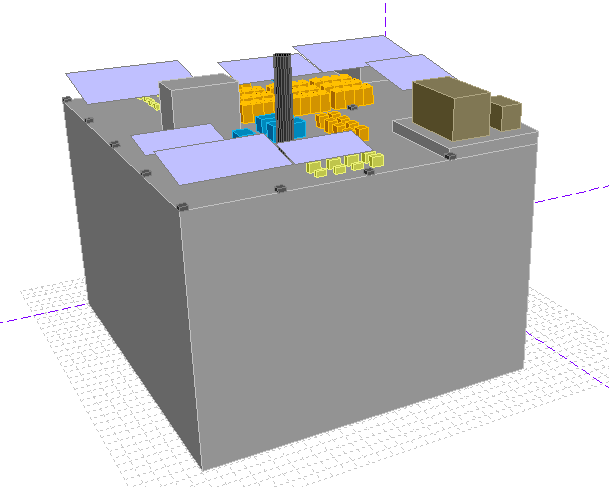

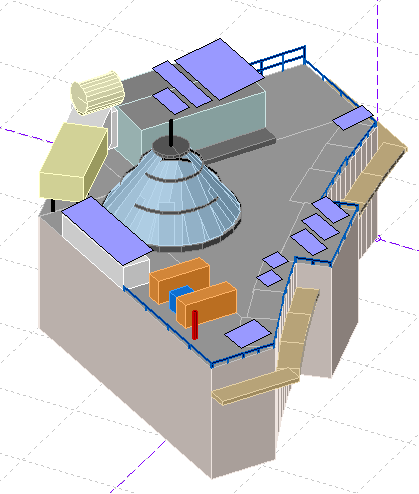

Feasibility Studies for Solar Power Plants for Industries

The project aims to install Solar PV power plants at selected Industrial clients, and operate autonomously in the private sector without receiving sovereign payment guarantees from the government, which is the case with Grid Connected IPPs. The project is regarded innovative and unique for Pakistan in the following ways:

- IPPs in Pakistan have always been set up by private investors to supply grid-connected electricity. PITCO will establish an IPP which will provide Distributed Power Generation at private sector clients’ site.

- PITCO long term Power Purchase Agreements (PPAs) are based on commercially negotiated terms with each client, which are naturally influenced by each client’s baseline cost of electricity.

- PITCO will be bearing all the financial and commercial risks of exchange rate fluctuations, grid cost and fuel cost variations etc. during the life of the PPA.

- The Power Purchaser / Facility Owner will receive clean power at 5% below its baseline cost of Electricity under its “Existing Facility Scenario”

Services Provided by PITCO

- Site survey and assessment of solar sites

- Feasibility study of solar sites

- Interconnection point assessment and capacity analysis

- System layout, planning and optimization

- System design, such as selection of key equipment like module type and brand, inverter type and brand, rack design, foundation design, and interconnection design

- Financial modelling, Cost and economy analyses

- Selection of protection equipment for DC and AC side of the system

- Preparation of specifications for Solar PV Modules, Solar Inverters

Name of client along with Installed PV Capacity:

- PTC – Pakistan Tobacco Company (2,702 KWp)

- Coca Cola Multan (1,900 KWp)

- Akzo Nobel (540 KWp)

- Philip Morris Sahiwal (525 KWp)

- Nestle DC Sheikhupura (239 KWp)

- Midas Safety Faisalabad (140 KWp)

- PPL Ahdi Oil Field Gujjar Khan (84 KWp)

- Nestle Kabirwala (80 KWp)

|

|

| PTC – Pakistan Tobacco Company (2,702 KWp) | Coca Cola Multan (1,900 KWp) |

|

|

| Akzo Nobel (540 KWp) | Philip Morris Sahiwal (525 KWp) |

|

|

| Nestle DC Sheikhupura(239 KWp) | Midas Safety Faisalabad (140 KWp) |

|

|

| PPL Ahdi Oil Field Gujjar Khan (84 KWp) | Nestle Kabirwala (80 KWp) |

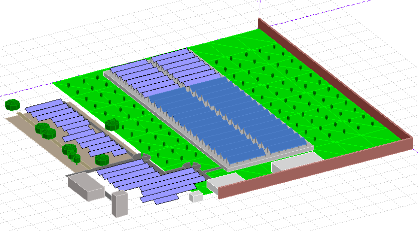

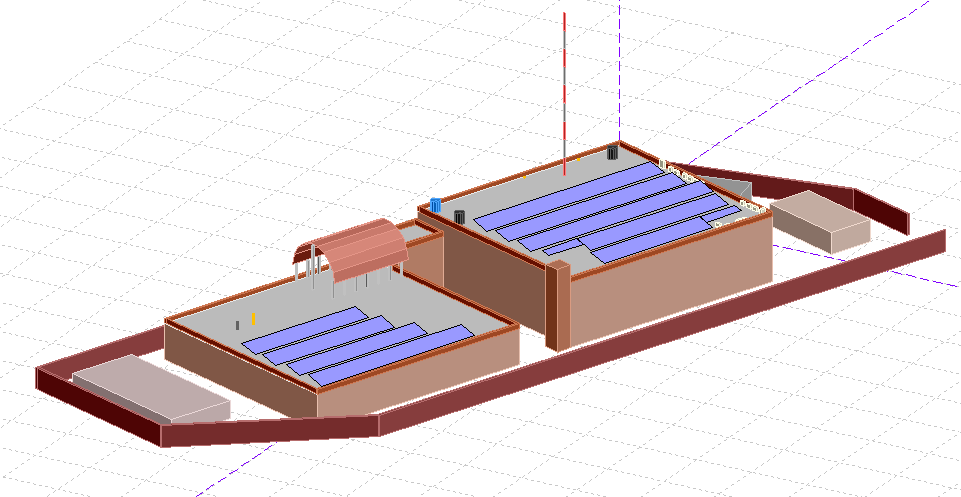

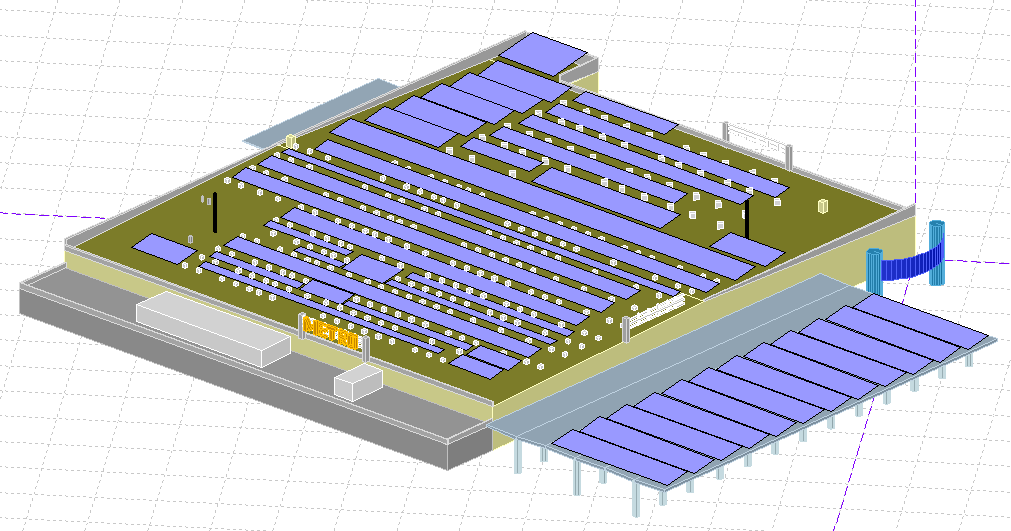

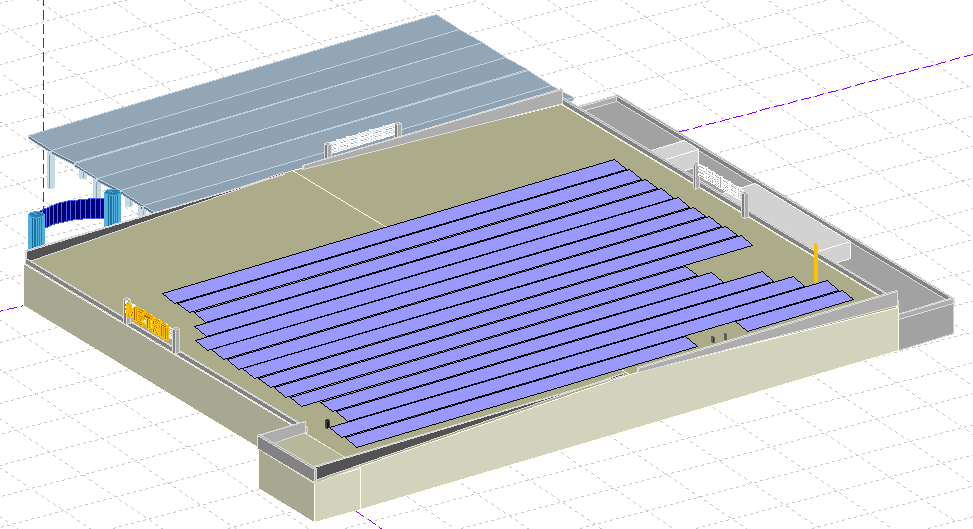

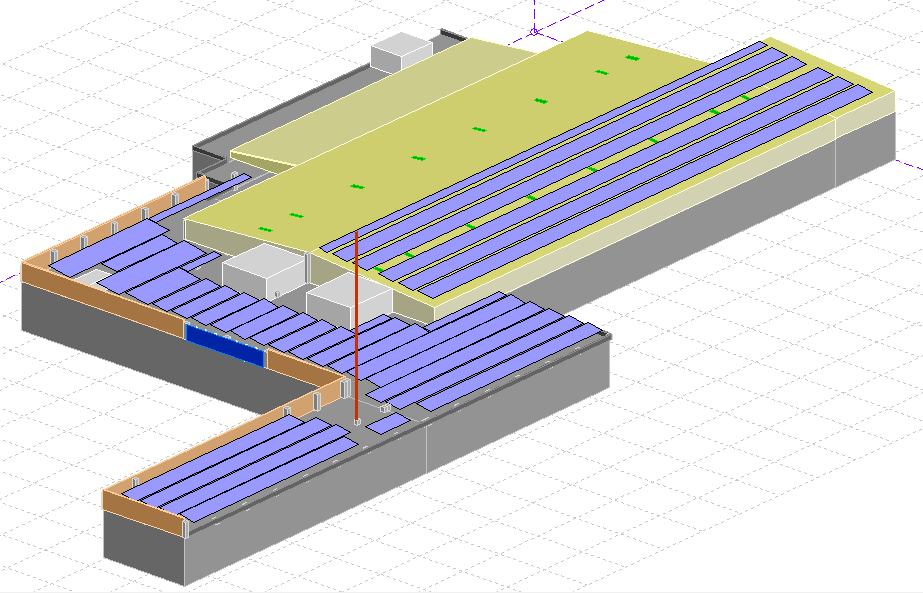

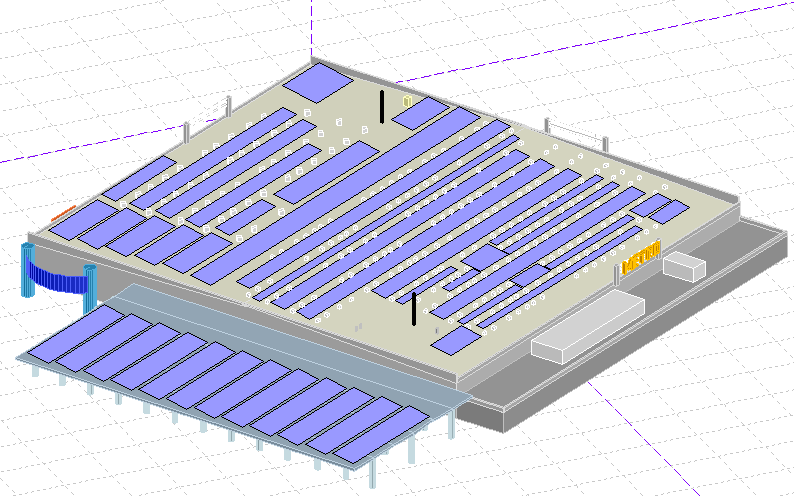

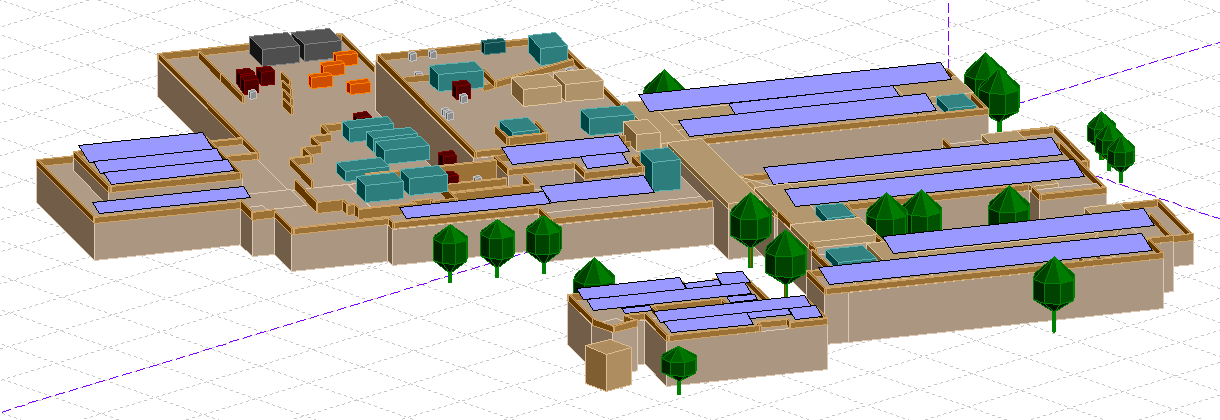

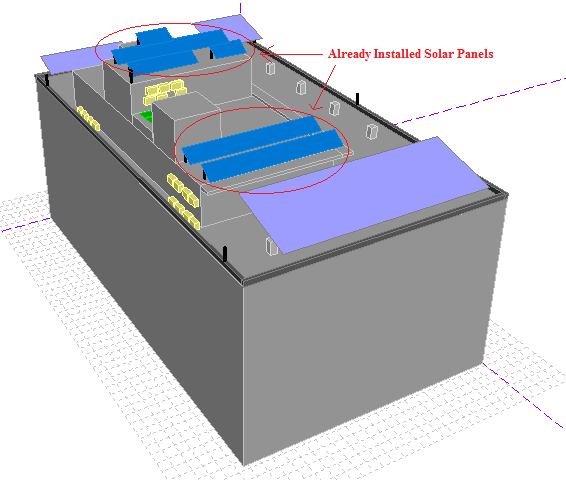

Feasibility Studies for Solar Power Plants for Commercial Sector

The project aims to install Solar PV power plants at Head Office of Iqbal Hamid Trust (IHT) and Eastern Carpet Limited (ECL), and operate autonomously without receiving sovereign payment guarantees from the government.

- Based on commercially negotiated terms, PITCO has signed long term Power Purchase Agreements (PPAs) with Iqbal Hamid Trust (IHT) and Eastern Carpet Limited (ECL).

- PITCO is bearing all the financial and commercial risks of exchange rate fluctuations, grid cost and fuel cost variations etc. during the life of the PPA.

- IHT and ECL are receiving clean power at 5% below their baseline cost of Electricity under its “Existing Facility Scenario”

Services Provided by PITCO

- Site survey and assessment of solar sites

- Feasibility study of solar sites

- Interconnection point assessment and capacity analysis

- System layout, planning and optimization

- System design, such as selection of key equipment like module type and brand, inverter type and brand, rack design, foundation design, and interconnection design

- Financial modelling, Cost and economy analyses

- Selection of protection equipment for DC and AC side of the system

- Preparation of specifications for Solar PV Modules, Solar Inverters

- Bids evaluation for different components of the system

- Power Plant erection and commission

- Run power generation on the building block for the facility key characteristics such as yield, Performance ratio, and capacity ratio

- System optimization based on different system configuration or equipment selection

Name of client along with Installed PV Capacity:

- Metro Faisalabad (842 KWp)

- Metro Airport Road Lahore (786 KWp)

- Metro Stargate Karachi (770 KWp)

- Metro Safari Karachi (758 KWp)

- Metro Thokar Niaz Baig Lahore (702 KWp)

- Metro Model Town Lahore (694 KWp)

- Metro Islamabad (673 KWp)

- Serena Hotel Faisalabad (365 KWp)

- Serena Hotel Quetta (337 KWp)

- Serena Hotel Islamabad (322 KWp)

- Telenor KLP Lahore (102 KW)

- World Bank – Main Building (85 KW)

- Telenor DHA Lahore (43 KWp)

- Bank Alfalah Gulberg Lahore (29 KWp)

- World Bank – Main Building (85 KW)

- World Bank – IFC Building (23 KW)

- Bank Alfalah Shahdin Manzil Lahore (21 KWp)

|

|

|

Metro Faisalabad (842 KWp) |

Metro Airport Road Lahore (786 KWp) |

|

|

|

Metro Stargate Karachi (770 KWp) |

Metro Safari Karachi (758 KWp) |

|

|

|

Metro Thokar Niaz Baig Lahore (702 KWp) |

Metro Model Town Lahore (694 KWp) |

|

|

|

Metro Islamabad (673 KWp) |

Metro Mangopir Karachi (585 KWp) |

|

|

|

Serena Hotel Faisalabad (365 KWp) |

Serena Hotel Quetta (337 KWp) |

|

|

|

Serena Hotel Islamabad (322 KWp) |

Telenor KLP Lahore (102 KW) |

|

|

|

World Bank – Main Building (85 KW) |

Telenor DHA Lahore (43 KWp) |

|

|

|

Bank Alfalah Gulberg Lahore (29 KWp) |

World Bank – IFC Building (23 KW) |

|

|

Bank Alfalah Shahdin Manzil Lahore (21 KWp) |

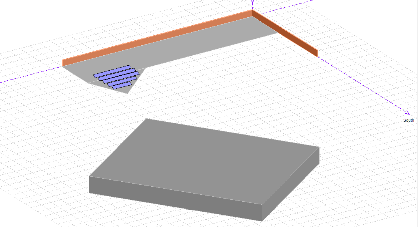

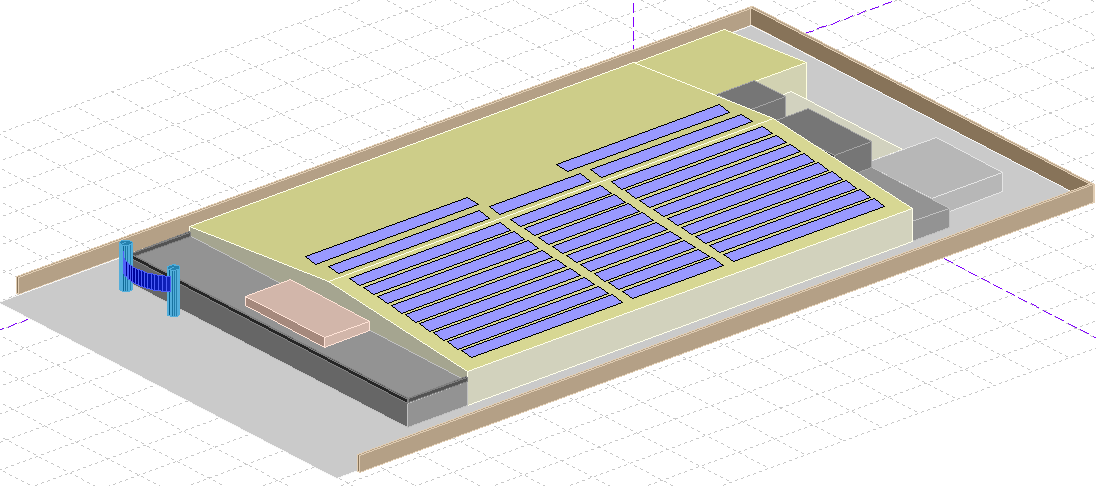

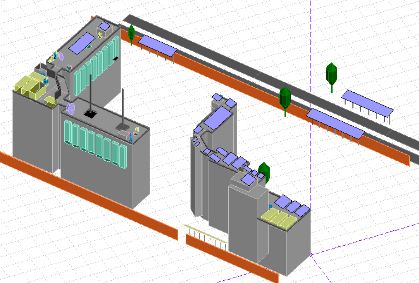

Installation of Solar Power Plants at IHT and ECL Head Office

The project aims to install Solar PV power plants at Head Office of Iqbal Hamid Trust (IHT) and Eastern Carpet Limited (ECL), and operate autonomously without receiving sovereign payment guarantees from the government.

- Based on commercially negotiated terms, PITCO has signed long term Power Purchase Agreements (PPAs) with Iqbal Hamid Trust (IHT) and Eastern Carpet Limited (ECL).

- PITCO is bearing all the financial and commercial risks of exchange rate fluctuations, grid cost and fuel cost variations etc. during the life of the PPA.

- IHT and ECL are receiving clean power at 5% below their baseline cost of Electricity under its “Existing Facility Scenario”

Services provided:

- Site survey and assessment of solar sites

- Feasibility study of solar sites

- Interconnection point assessment and capacity analysis

- System layout, planning and optimization

- System design, such as selection of key equipment like module type and brand, inverter type and brand, rack design, foundation design, and interconnection design

- Financial modelling, Cost and economy analyses

- Selection of protection equipment for DC and AC side of the system

- Preparation of specifications for Solar PV Modules, Solar Inverters

- Bids evaluation for different components of the system

- Power Plant erection and commission

- Run power generation on the building block for the facility key characteristics such as yield, Performance ratio, and capacity ratio

- System optimization based on different system configuration or equipment selection

|

|

|

Solar Power Plant at Eastern Carpet (Pvt) Ltd |

Solar Power Plant at Iqbal Hamid Trust |

USAID Power Distribution Program (PDP)

Power Distribution Program (PDP) aims to facilitate improvements in electric power distribution utilities across Pakistan. PDP is designed to transform the electricity sector, particularly the distribution companies (DISCOs). The challenges are significant and DISCOs sit at the nexus of the problems that prevent long-term sustainability of the power sector. Loss levels are staggering, operations are inefficient, tariffs are unrealistic, corruption is pervasive, and demoralized utility staffs too often lack the capacity needed to perform effectively. The project is being undertaken by International Resources Group – IRG (USA). PITCO is the local partner for the project, and has dedicated team of experts working across eight DISCOs throughout the county. Our scope of work includes:

- Operational audit of participating DISCOs

- Development of comprehensive performance improvement action plan for DISCOs

- Development of action plans for MWP and NEPRA

- Comprehensive analysis of cost of service and tariff design

- Legal and policy review of DISCOs and NEPRA

- Human resource development and change management

- Identification of options for reduction of theft and corruption

- GIS Mapping of Distribution System

- GPS survey of electrical consumers and network assets

- GIS base map and digitization of electrical network assets (Feeders, Transformers, and Poles)

- Consumer Census for Upgrading Consumer Information System

Smart Metering at Industrial & Residential Consumers

The project objective is to lay foundation for Peshawar Electric Supply Company (PESCO) to combine Smart Metering with demand response, intelligent control and distribution automation. The implementation of project aims to set pace for organization wide implementation of AMI technologies to meet the needs of all service territories. PITCO’s team of experts is involved in implementation of smart metering initiative for 12,000 Industrial and 42,000 residential consumers at PESCO. PITCO has been involved in:

- Preparation of bidding documents and technical specifications

- Evaluation of bids, tendering, and vendor shot-listing.

- Development of process flows & SOPs for data communications

- Preparation of mechanisms for monitoring communication processes between meter, modem & control center

- Development of procedures for sharing energy data (load profiles,consumption, and billing data) to concerned departments

- Installation, commissioning & testing of complete system

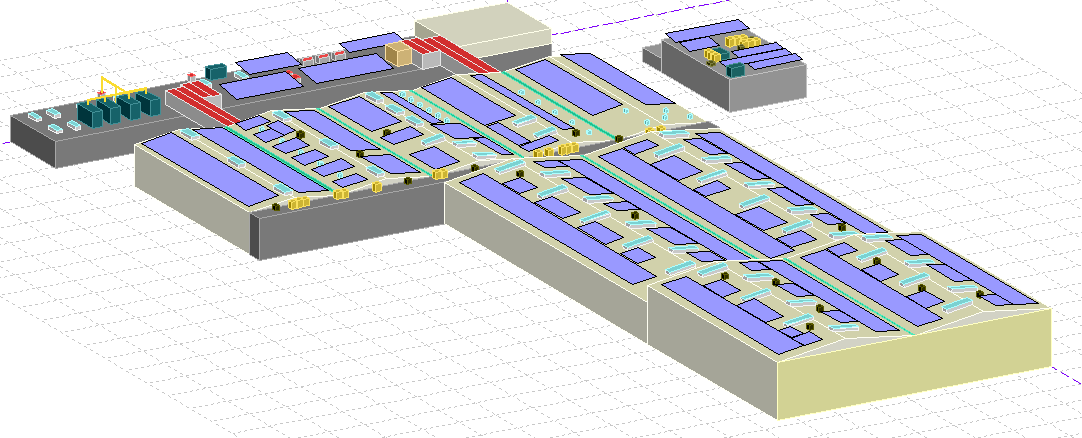

Smart Metering at Residential, Industrial, Agriculture Consumers and Distribution Transformers

As field implementation manager, PITCO is involved in planning, designing and implementation of a standalone Meter Data Collection (MDC) system, and managing it centrally for five (05) DISCOs. The MDC system is being deployed for residential, industrial, commercial, and agricultural consumers and for energy accounting at distribution transformers. The project involves 17,000 metering nodes spread across all participating DISCOs. PITCO has been involved in:

- Participation in preparation of feasibility studies, and technical due diligence

- Preparation of requirements, engineering design, and technical architecture of business solution

- Preparation of specifications for solution components i.e. MDC System, Communication Network, Co-Located Data Center, etc.

- Preparation of specifications and bidding documents for solution components i.e. AMR meters, MDC System, Communication Network, Co-Located Data Center, etc.

- Technical evaluation of proposals and vendor short-listing

- Review and evaluation of factory acceptance tests of the material

- Development of process flows & SOPs for data communications

- Planning remote acquisition of energy data as load profiles at instantaneous, planned & periodic intervals

- Preparation of mechanisms for monitoring communication processes between meter, modem & control center

- Planning system administration tasks i.e. user creation, role definition, and scheduling meter data back-ups

- Provision of insight on visualization of time-series data grouped on the basis of time duration, load pro-file or meter stations in the shape of graphs & tables

- Developing procedures for sharing energy data (load profiles, consumption, and billing data) to concerned departments

- Designing of report formats and provision of remote web access to energy data

- Installation/commissioning and end to end testing of system

- Implementation of GPRS based VPN for data connectivity between field devices and back-end system through telecommunication service provider

- Technical evaluation of overall solution

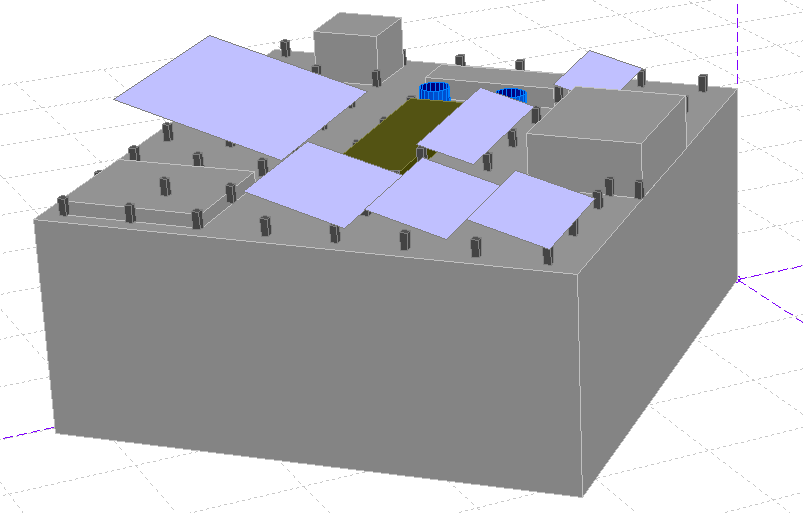

GIS Mapping, Load Flow Analysis and Feeder Rehabilitation Proposals of Distribution System

As part of program activities, PDP team has demonstrated use of Geographical Information System (GIS) for mapping the HT/ LT consumers and electrical network assets, on a geographical base map, to help define the consumer’s electrical connectivity across all targeted DISCOs. PITCO has conducted GIS mapping, load flow analysis and prepared feeder rehabilitation proposals of more than 512 feeders all across Pakistan, covering a total length of more than 12,000 km of HT and LT network across the 9 state owned electricity distribution companies. GPS survey has been conducted for geo-referencing and mapping the relevant electrical assets on the digital base map. GPS survey of electrical consumers and network assets involved identification of all consumers and their service connections, followed by the preparation of GIS base map and digitization of electrical network assets (Feeders, Transformers, and Poles). The purpose was to demonstrate wide range of solutions associated with GIS encompassing the entire business value chain in the power distribution sector – from setting up distribution network and load management to customer information, assets management, billing and customer services. This work was coupled with building a bridge between the GIS geo database in ESRI, as the load flow software so that the GIS data collected in the field could be cleaned up in ESRI, and then exported directly to the load flow analysis software. This was followed by conducting HT and LT load flow analysis of the distribution network, so that a segregation of technical and non-technical losses could be carried out. This was later coupled with HT and LT feeder rehabilitation proposals that were developed for the utility so that the technical losses could be reduced.

Advanced Meter Reading (AMR) System

As a part of program activities, PITCO is implementing a standalone software for the Meter Data Collection (MDC) centrally managed by PDP for 5 Power Distribution Companies (DISCOs). Meter data collection (MDC) system is being deployed for 17,000 metering points which include AMRs on distribution transformers, Commercial, Industrial and Residential meters. The AMR head-end system is designed to be co-located at data center in Lahore, which will provide shared infrastructure and services to the five DISCOs where the AMRs will be installed under the program. The DISCOs are provided remote access through secure private and self-healing physical and logical MPLS L3 VPN links to the meter data repository applications hosted at the service provider’s Data Center, central hosting facility to use the meter readings for billing and monitoring. Additionally, the project will involve GSM/GPRS communication on the AMR meters, which is covering point to point communication. The project involved working with Islamabad Electric Supply Company (IESCO), Peshawar Electric Supply Company (PESCO), Lahore Electric Supply Company (LESCO), Hyderabad Electric Supply Company (HESCO) and Multan Electric Power Company (MEPCO). This project is the first AMR project in Pakistan, and will provide a road map and scalable platform to the DISCOs to implement smart metering projects in the future.

Financial Management of Power Distribution Companies

- Preparation of a 10 year financial forecast model to allow the utilities to better plan their financial forecasts, including budgetary planning, financial forecasting, project financing, cash flows, etc.

- Preparation and implementation of financial accounting manual, with revised book of financial powers, including new process flows which envision a full scale ERP implementation

- Development and implementation of revised internal audit manual, including the realignment of the internal audit function and implementing outsourced external co-auditing function Implementing new tariff petition process which involves carrying out a real cost of service study, to allow the utility to calculate its real cost of delivery of electricity to all category of consumers

- Data collection and verification through AMRs installed on selected distribution feeders for verification of load allocations for various categories of consumers

- Structuring Tariff Design, based on justifiability, transparency, and simplicity, to give price signals to consumers for efficient utilization of electricity

Cost of Service Study & Tariff Design

- Cost of Service & Tariff Design

- Development of customized Cost of Service (CoS) Mode to allow DISCOs to calculate cost reflective tariffs and support for implementation of CoS Model

- Revenue Requirement Estimation involving analysis of financial statements, budgets, capital expansion plans, sales, and demand and load data projections

- Selection of appropriate methodology to allocate costs to different customer categories

- Installation of AMR meters at selected feeders across all 9 DISCOs to improve the quality of input data for Cost of Service study

- Training sessions for DISCO & NEPRA professionals on CoS, Performance Benchmarking, Strategic Planning, Balance Score Card development and implementation

- Assistance to NEPRA

- Improvement in regulatory guidance for DISCOs regarding power acquisition

- Development of vision of the competitive market structure based on international best practices

- Review of Tariff rules and regulations and recommend modifications and more efficient approaches for Tariff determination

- Assessment and establishment of relationship between NEPRA and international regulatory bodies (regional or countries with similar conditions) and facilitation in out/in-country training and information exchange.

Change Management & Human Resource Management

- Technical assistance in specialist areas of HR, training and capacity building

- Identification of critical success factors in terms of change management

- Development of change management strategy and training and development plan

- Organizational Re-organization of 2 of the DISCOs, which included the following:

- Updating the old WAPDA HR Manual, and converting into an updated Policies & Procedures document

- Job Classification, including job descriptions and KPIs for each position

- Performance Management System to replace the old ACR/PER system

- Compensation and Benefits study to propose revised salary packages which are reflective of the market

- Organizational Assessment Study & Restructuring strategy of the entire DISCO

- Implementation of a HRIS system for the entire DISCO

- Development of a long term training & capacity building plan

PITCO also carried out an Organizational Restructuring at NEPRA

- Job Classification, including job descriptions and KPIs for each position

- Performance Management System

- Compensation and Benefits study to propose revised salary packages which are reflective of the market

Engineering and Operations

- Setup Planning & Engineering Centers across all 8 DISCOs

- Setup modern state of the art P&E centers

- Trained DISCOs on using GIS based mapping technique for distribution system mapping

- Trained DISCOs on converting GIS data into modern load flow analysis software for technical loss calculations, and segregating technical and non-technical (Commercial) losses

- Implemented Pakistan’s first wide scale AMR project in 5 DISCOs

- Implemented Pakistan’s first AMR solution for the domestic and commercial consumers, by installing a centralized data center hosted at Wateen’s Data Center, and connected it to 5 DISCOs across Pakistan

- Installed 14,000 AMRs in a high loss sub division at Hyderabad, reducing meter reading cycle to 1 day from 31 days.

- Provides daily monitoring of consumer load, consumption, and other key parameters to curtail theft

- Also installed AMR meters on distribution transformers at various feeders in Lahore, Multan and Islamabad to demonstrate energy accounting principles and linking transformer readings to downstream consumers billing

- Setup Load Dispatch Centers at all 8 DISCOs

- Setup LDI project country wide, which has installed AMRs on all outgoing feeders across Pakistan

- Has allowed the DISCOs to monitor their demand and supply, and eliminate forced load shedding

DISCO Commercial Operations

- Implementation of Hand Held Unit System

- Implemented HHU based system for meter reading using pictures and manual key punching

- Linked it with the billing system so that manual manipulation of meter readings could be eliminated

- Implemented RF enabled Meter Reading System

- Implemented first walk by system in Pakistan, whereby meter readers will read the meters by walking on the street

- Minimum human interaction

- Implementing Customer Information System (CIS) at one division

- Have been involved in defining the business rules for implementing a CIS at one DISCO

- This has replaced the old COBOL legacy based system

Consumer Census for Upgrading Consumer Information System

Consumer census has been carried out in a selected subdivision for updating Consumer Information System (CIS) and integrating GIS data with CIS. Consumer Census Team comprising of Enumerators and GIS Surveyors are involved in comprehensive data collection activity. The information collected during the census is aimed to update CIS for contact information consumer, type of usage, meter particulars, actual load, and GIS coordinates. The census has not only demonstrated efficient mechanism for updating CIS and incorporating GIS information at the same time, it has also highlighted the need of effective communication link between consumer and DISCO for resolution of issues and complaints.

Checking, Testing and Rehabilitation of Meters

PDP teams have undertaken Meter Checking, Testing and Rehabilitation work on 2 sub divisions in LESCO and PESCO respectively, and have been involved in replacing and rehabilitating more than 40,000 electronic meters in these utilities. The activity was followed up with auditing of the meter reading routes, and this has led to an increase in revenue of approximately US $ 1 million in additional revenue for these utilities.

|

|

|

Typical Poor Condition of Meters and Service Cables |

After PDP Initiative |

In addition to rehabilitation of meters, service cable network was also fixed.

|

|

|

Poor Condition of Service Cables |

After PDP Initiative |

The initiative was implemented not only to demonstrate considerable reduction in energy losses, but also to highlight associated benefits like uninterrupted electric supply to consumers and theft control.

USAID Energy Efficiency & Capacity (EEC) Project

- Energy Efficiency in Agriculture

- Replacement of inefficient Municipal Water Pumping Systems

- Inefficient Industrial Motor Replacements

- LT Capacitor Installation Program

Operational Audits of Power Distribution Companies

PITCO carried out operational audits of all 8 state owned electricity distribution companies, which mapped the processes in key areas of

- Finance

- Engineering & operations

- Commercial

- Human Resources

- Communications

- Change Management

Based on these, Performance Improvement Action Plans were prepared for all the companies, which outlined long term investment needs, and also short term pilot projects which were funded by USAID. The specific projects were in all the key functional areas of the DISCOs, along with a cost benefit analysis.

Demand Side Management (DSM)

As part of the EEC Project, PITCO was involved in preparing an elaborate Power Conservation Action Plans at 4 electricity distribution utilities in Pakistan, i.e. MEPCO, HESCO, PESCO and QESCO. A team of PITCO specialists at each of the distribution companies setup the DSM Cell at the DISCOs. As part of this initiative, PITCO reviewed the existing organizational and operational structure of the DISCOs, their customer profiles, and transmission and distribution network profiles. The project is being implemented by International Resources Group – IRG (USA) and PITCO is the local partner for the project. Detailed Power Conservation Action Plans were developed for the DISCOs, which included a comprehensive data collection exercise to collect system load profile data (with temperature sensitivity analysis), customer profile data, customer billing, collections and revenue data. Additionally, load research was carried out to prepare representative load profiles for various customer categories (Commercial, Domestic, Industrial, etc.), and temperature sensitivity analysis was carried out to understand the peak usages of the various consumer categories. Additionally, specific problem areas were identified and analyzed, which included losses in the distribution network, transformer burn out rate, theft of electricity, etc. A comprehensive DSM Program was developed as a result of these Power Conservation Plans, to address each of the problem areas identified in the plans, which included DSM analysis such as benefit cost ratios, participant, utility, resources and total cost prospective. Each of the Plans included thorough financial and technical analysis of the options, and the benefits to the utility, consumers and the upstream power players (NTDC, PEPCO, etc.).

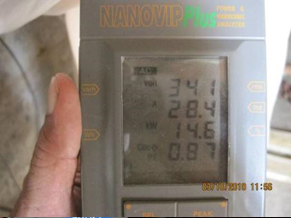

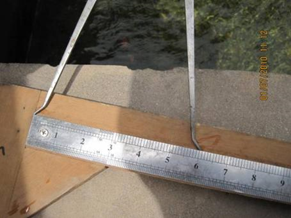

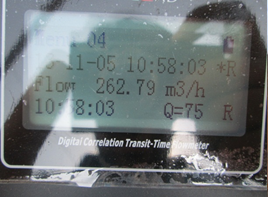

Energy Efficiency in Agriculture

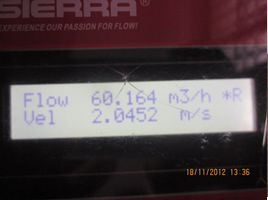

Call Center As part of project activities, PITCO established a dedicated call center was setup with call back facility. The call center was the primary contact for farmers who wish to get their inefficient pump sets replaced with energy efficient ones. More than 15,000 farmers were registered with the Call Center (either they called in, or outward calls were made from the Call Center). Information for those interested farmers were passed on to the energy audit teams for pre installation energy auditing and then to pump suppliers for establishing contacts and order confirmation. Farmer Meetings To raise awareness and to disseminate the benefits of the program, PITCO along with Pump Suppliers organized farmer meetings at District, Tehsil, and village level. More than 100 such meetings were organized across Sindh, Punjab and KPK. These meetings attracted over 8, 500 farmers for interactive discussions on energy efficiency, and allowed them to hear firsthand about electricity savings from farmers who had already replaced their pumpsets. Farmer Data Collection An online portal application was developed, by PITCO’s in-house software development team, to cater to the needs of the call center, energy audit teams, pump suppliers, and project management team. While attending an incoming call, each Call Center Representatives were required to record farmer and existing pump set information. The information entered helped the project management team in initial screening and evaluation of the case and devising followup strategy. Replacement of Pump Sets Followed by marketing and outreach activities, PITCO’s Energy Audit Teams conducted pre installation visits to the farmers’ sites (which included the energy audit and sizing of the energy efficient pump). Selected Pump Suppliers then take orders from interested farmers and install energy efficient pump sets. PITCO’s Energy Audit Teams visited farmers’ sites again to conduct Post Installation Energy Audits for calculation of resultant energy savings. Energy Auditing PITCO’s Energy Audit Teams undertook comprehensive energy audits of almost 10,000 pump sets for collection of detailed information such as details about pumps and motors (type, make, age, and rating) water requirements, status of meter installation, electrical consumption (voltage, current, power factor, and power consumption), underground water level in different seasons, power supply pattern, and the farmer’s willingness to participate in the Program. Existing Pump Set Performance Evaluation & Replacement Pump Set Sizing For all pump sets being audited, a detailed analysis was carried out by measuring the suction and discharge head, power input and water flow to evaluate the operating efficiency of all the pump sets. Based on the audit study, an efficiency index for the existing pumping system was prepared. After evaluation of existing pump set performance and operating efficiency, the capacity and type of new energy efficient pump sets to replace the existing pumps for the same discharge was determined. Optimum sizing of pump sets is essential to ensure same water discharge rates led and more optimal energy use. Post Replacement Energy Auditing After replacement, PITCO energy audit teams conducted detailed energy audits of energy efficient pumps and motors for measuring energy consumption and efficiency and to establish the peak demand savings that these pump sets have led to. Energy Savings Calculations The energy saving potential that can be achieved by replacing existing pumps with that of the energy efficient pump set was quantified based on the analysis of the measurements. A detailed cost benefit analysis associated with the implementation of each of the proposed energy conservation measure was undertaken by dedicated team of engineers.

Tubewell Efficiency Improvement Program

An integral part of the EEC project is to demonstrate Demand Side Management practices through pilot initiative. TWEIP has been designed to demonstrate the potential to significantly improve the efficiency of the use of electricity in the world’s largest irrigation-based agricultural system. The project has a target to replace 11,000 inefficient tubewell pump sets with efficient ones across 7 DISCOs in Pakistan. With 11,000 replacements the project aims to reduce peak demand for electricity by approximately 45 MW and annual energy savings of 115.5 GWh. The project is being implemented by International Resources Group – IRG (USA) and PITCO is the local partner for the project.

|

|

A Comprehensive Marketing Strategy has been developed to create awareness among farmers and communicate the benefits of replacing their current tube well pump sets with energy efficient pump sets. After identification of target segment (high end consumers of electricity in agricultural sector), newspaper advertisements and brochures are published, Awareness Raising Seminars are organized, and a dedicated Call Center is established for dissemination of information and enrollment of farmers in the program. Each DISCOs monthly electricity bill carries Program’s advertisements. Once a farmer is enrolled in the project, comprehensive onsite Energy Audit is conducted for collection of general information about the pump set, civil work conditions, measurements of electrical values (voltage, current, power factor, and input power) and water discharge, and calculations of head, efficiency and flow of existing pump set. Based on energy audit data and calculated parameters, precise resizing of pump set is done to ensure enhanced efficiency and energy savings. Post implementation energy audits are conducted, after installation of new pump set, to ensure realization of envisioned energy savings.

|

|

|

Measurement of Energy Consumption |

|

|

|

|

Measurement of Delivery Pipe Diameter |

|

|

|

|

Measurement of Flow and Delivery Length |

|

|

|

|

Measurement of Static & Dynamic Water Level |

|

Based on the results of 4,583 Pre-replacement Energy Audits conducted across seven participating DISCOs, the energy demand savings through replacement of inefficient tubewell pumpsets with new energy efficient tubewell pumpsets are expected to be 27.61 MW.

Replacement of inefficient Municipal Water Pumping Systems

Nationwide, electricity consumption by tubewell pumpsets amounts to 15% of the total annual energy consumption, with substantial variation from one DISCO to another. Most of the Tubewells & pump-sets operating in Municipalities under different DISCOs are highly inefficient, worn out and relatively consuming very high energy to operate. The efficiency level of these pumps ranges between 18 to 45% whereas the service time of the pumping stations is about 21 hrs / day being essential to cater the needs of households. The replacement of inefficient Municipal Water Pumping Systems aims to replace inefficient motor pumpsets replacement in the publicly-owned water and sewerage utilities. These municipal water and sewerage pumpsets are a large load on each Pakistani DISCO. The energy audits and savings calculations for the municipal pumpset replacement program have been carried out along the same lines as the “Energy Efficiency in Agriculture” Program. PITCO’s Energy Audit Teams have undertaken pre-replacement and post-replacement energy audits of over 200 municipal pumpsets. The replacement of 135 tube-well pump-sets at Capital Development Authority (CDA) and 75 tube-well pump-sets at Karachi Water and Sewerage Board (KWSB) was carried out as part of project activities. The project was implemented by engaging three ISO-9906 certified pump-suppliers (KSB, MAK and HMA). Municipalities Pump Replacement Program was designed and implemented to

- To demonstrate the potential of energy conservation to the Municipalities.

- Exhibit multiple benefits of this program to encourage Utility Companies for adoption of the same methodology future replacement and expansion plan.

- Setting up of trend to use ISO-9906 standardized & reliable pump-sets for cutting the extra cost incurred on variety of material inventory maintained for repair and maintenance.

- Reduce considerable amount of peak energy demand from respective DISCOs.

- Improved availability of water thru energy efficient and appropriate equipment to better serve the already water deprived areas due to inefficient pump-sets.

- Training of the tubewell operators for proper use and handling of replaced submersible pump-sets particularly replaced against turbines.

- Awareness raising amongst the engineering team of municipalities about the importance of energy auditing to understand consumption of energy vis a vis flow for timely and effective planning of replacement.

|

|

| The replacement of 135 tubewell pump-sets in CDA under USAID-PDP program reduced peak demand by 1.07MW. | In case of KW&SB, 75 pump-sets replacement reduced peak demand of 1.36MW. |

PITCO was involved in implementation of following activities throughout project life cycle,

- Pre installation energy audit

The pre installation energy audit at 145 & 294 identified sites of CDA & KW&SB respectively was conducted to know the existing performance of the pump-sets, its flow and energy consumption. All pre installation energy audit results were submitted to the concerned Municipalities for their assessment and identification of sites for replacement to get the maximum benefit from this program.

- Sizing of Pump-sets and Installation

Based on pre installation energy audit data and considering the requirements at Municipality’s sites, most suitable pumps with appropriate motors were proposed to the pump-suppliers out of their models and after consultation and review, the final sizing with ancillary items was submitted to the suppliers. The Material Requisitions were prepared by the pump-suppliers and submitted to the program engineers for review and vetting before further submission to concerned Utilities

- Post installation energy audit

The post installation energy audits of replaced tubewells at CDA and KW&SB were conducted to develop the comparison of pump-set’s performance to ensure that replacements are in line with the program criteria.

|

|

|

Measurement of Flow |

|

|

|

|

Measurement of Pipe Diameter & Head |

|

|

|

|

Measurement of Water Level and Collection of GPS Coordinates |

|

- Rework and modification of pump-sets not conforming to the program’s criteria

All the underperforming replacement sites were identified to the suppliers for improvement, modification and even change of equipment to meet the required parameters set by the program.

- Re-post installation energy audit of modified pump-set sites

After rework & rectification of problematic sites, re-post installation energy audits were conducted to ensure that the problem is resolved, in case the pump-set does not meet the program’s criteria, the concerned supplier was again asked to resolve the issue either by modifications or putting the new pump-set.

- Recovery of old pump-sets for destruction and converting into scrap

Recovery of old pump-sets from municipalities thru the pump-supplier was managed to avoid reuse of the inefficient equipment by the beneficiary. After verification and checking destruction of old equipment at program warehouse was ensured thru the contractor.

- Monitoring, coordination and reporting of the project

Regular monitoring of all the program activities like pre & post installation energy audit, delivery of equipment, installation pace and retrieval of old confiscated equipment was conducted and coordination with vendors, municipalities and other stakeholders was a regular feature throughout the program.

Inefficient Industrial Motor Replacements

Industrial Motors Replacement program, a Demand Side Management (DSM) initiative, is being implemented across all 9 power distribution companies of Pakistan. The program engagement is through three leading Motor Companies supplying efficient motors (ABB, SIEMENS and WEG/AVANCEON) to industries located across the country. Activities performed by PITCO include: Energy Auditing PITCO’s Energy Audit Teams undertook comprehensive energy audits of inefficient industrial motors for collection of detailed information such as Facility Information, General Data, Key Electrical Parameters (Voltage, Current, Power Factor (PF), Frequency, Input Power, Active power, Reactive power, etc.), and Other Parameters (Motor temperature, Shaft speed, Bearing temperature, Motor vibrations, Bearing vibrations, etc.).

PITCO’s Energy Audit Team have conducted pre-replacement audits of over 2100 inefficient industrial motors. Existing Motor Performance Evaluation A detailed energy efficiency analysis was carried out for all audited motors. The analysis took into account parameters such as operating hours, mode of operation, loading, electrical parameters, etc. Only motors with an operational efficiency of less than 85% were recommended for replacement. Post Replacement Energy Auditing After replacement, PITCO energy audit teams conducted detailed energy audits of the new energy efficient motors for measuring energy consumption and efficiency to establish the energy savings as a result of these replacements. PITCO’s Energy Audit Team have conducted post-replacement audits of over 1300 energy efficient industrial motors and 600 VFDs. Energy Savings Calculations Actual energy savings for each motor replacement was established through information collected from the Post-replacement energy audit as well as the Pre-replacement energy audit. The initiative is expected to achieve energy saving of 8 MW through operational efficiency improvement in industrial sector.

LT Capacitor Installation Program

The project aims to install 150,704 Low Tension (LT) capacitors on agriculture tubewells connected to 9 DISCOs, i.e. QESCO, MEPCO, LESCO, FESCO, PESCO, HESCO, SEPCO, GEPCO, and IESCO. The objective is to reduce the reactive power demand on the system, lowering currents levels, and thus reducing demand & technical losses. Most of the rural feeders, especially those who predominantly serve tubewell loads, are being operated with Low Power Factor (mainly due to sub-standard / refurbished motors) and thus cause increased distribution losses. The project aims to reduce energy loss resulting from these inefficient tubewell motors on the feeders, by installing low tension (LT) capacitors at the consumer end. In addition to reduced energy losses, tubewell load demand will also be reduced considerably with improved power factor. Major activities undertaken by PITCO:

- Measurement and record of pre-installation data (kW, kVA, kVAr, V, Amperes and Power Factor) of the induction motor installed on the Tubewell, to evaluate the kVAr values and determine the nearest available proper size of required LT capacitor.

- Installation of properly sized LT capacitor after evaluation of the pre-installation energy audit data

- Measurement and record of post-installation data (kW, kVA, kVAr, V, Amperes and Power Factor) to ensure that an appropriately sized LT Capacitor (resulting in at least a power factor value of 0.95) had been installed.

- Preparation of Energy Savings based on Pre and Post Installation energy audit data.

GIS Mapping of Project Activities

As part of Tubewell Efficiency Improvement Program, GIS has been used as a valuable tool to locate and monitor project activities. Additionally, GPS coordinates are used to plot both pre & post audit activities carried out throughout the county.

|

GIS Application Development

As part of Tubewell Efficiency Improvement Program, PITCO’s dedicated team of expert developed a customized application for analysis of data, identification of area specific activities, and geographic mapping of areas with high energy saving potential.

| |

GIS locations of different types of farmer tubewells, searchable by pumpset efficiency, water table depth, efficiency, and other characteristics.

The solutions empower decision maker in identifying areas with specific energy efficiency, water table depth, water flow, water pumping hours, delivery head, land holding, and energy consumption of different types of tubewell pumpsets.

GIS Mapping of DISCOs

Expanding power supply compass has increased the need of effective and efficient resource planning, implementation of projects, and maintenance of quality services. To address these needs and requirements, a comprehensive enterprise resource planning coupled with utility mapping services is essential.

Distribution System

PITCO’s is currently involved in implementation of GIS electricity utility mapping services to plan, control, and co-ordinate critical areas in power supply, such as outage management, geographical database planning, distribution management, supply line management, installations management, etc. Our activities include,

- Geo-Database creation

- Integration of Consumer Information with Geo-database

- GPS Field Inventory

- Meter Reading, Testing, and Installation

- Distribution Line Locating

- Load Flow Analysis

- GIS based Customized Applications Development

Electricity Consumers – Superimposed on GeoMap

GIS Surveying

Spatial survey adds accuracy to any kind of raw technical as well as non-technical data available on ground. GIS based survey gives the answers to all potential questions which need to be answered for efficient resource management. Our services enable our clients to know what is where, how it is there, and why it is important. During GIS survey we consider following factors for delivering highly accurate data,

- Highly qualified Surveyors and GIS Specialists

- Automation of data digitization

- Quality assurance of non-spatial & spatial data

- Synchronization of GIS data and non-spatial data

USAID Support for Privatization Activity

The project is funded by USAID to provide significant assistance to the Government of Pakistan (GOP) to achieve the structural benchmarks related to privatization as well as the GOP’s longer term privatization agenda. In addition, the project aims to support the Privatization Commission’s (PC) efforts to administer and manage the privatization agenda and supporting the PC’s efforts to reform the corporate governance structure of Public Sector Enterprises (PSEs). Target areas for privatization are Aviation, Oil & Gas, Power, Banking & Finance, and Insurance PSEs. The initiative covers the following tasks:

Evaluation & Assessment: Evaluation, restructuring, and business plans for various entities prior to privatization, and undertaking skills gap analysis of the Privatization Commission and additional staffing needs

Staffing an Expert Panel: This includes sector experts transaction advisory, legal specialists, and financial/valuation experts as required through the life of the activity to assist the PC in completing sector assessments (to include competition assessment studies) in each of the five sectors prioritized by the PC (currently power distribution, production, insurance, industry, and aviation)

Privatization Research Studies: Rapid review of the private participation experience of previous privatization efforts, with reference to relevant international examples of private participation

Privatization Readiness Reports: Development of reports on prospects for private investment of each PSE being targeted by the PC, encompassing a review of the financial health and operational performance of each PSE , and the requirements for private sector participation, including modes of private participation (e.g. management contracts, concession agreements, and divestiture).

Restructuring Roadmaps: Preparation of restructuring roadmaps with the objective of creating institutional conditions which are optimal for attracting private investment

PITCO is a sub-contractor to Crown Agents on this project.

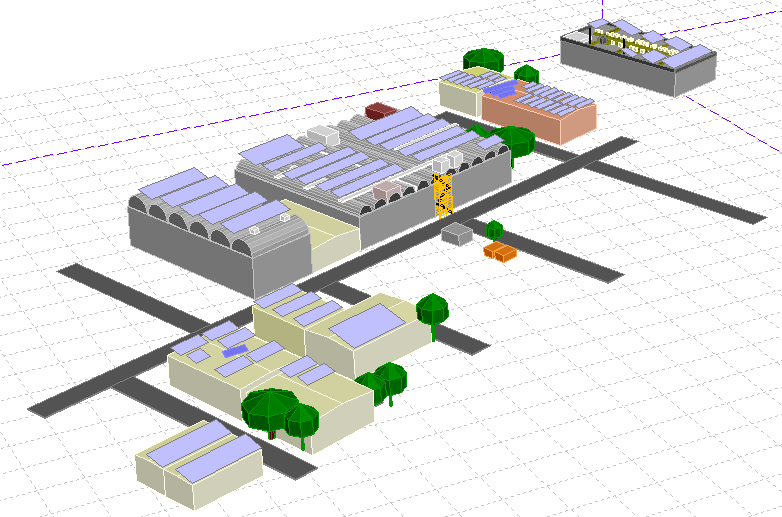

USTDA Project: Biomass Power Plant and Waste Heat Recovery for Cement Producer

Pioneer Cement Limited (PCL) is experiencing the impacts of unreliable electricity – specifically, economic damage due to loss of productivity. This impedes business activity by increasing costs and negatively impacting the company’s ability to provide reliable cement supply for its customers. The increase in cost and uncertainty reduces Pioneer Cement’s ability to attract Pakistani and international investors, and negatively impacts employment, wage levels, and overall economic development. Pioneer Cement Limited’s approach to resolving the unreliable electricity supply issues consists of the following environmentally friendly projects:

- Installation of 50MW Biomass Based Power Plant

- Installation of 7MW Waste Heat Recovery Unit

- Replacement of Inefficient Motors with High Efficiency Motors

Services provided by PITCO:

- Detailed review of existing technical conditions and operations of the plant

- Comprehensive technical review of existing plant power distribution system

- Detailed analysis for long term biomass fuel supply chain

- Recommendations on appropriate power plant technology to utilize proposed fuel mix

- Preparation of land requirement, plant layout, civil, mechanical, electrical, and equipment layout at the site

- Assessment of power plant connection and power export / import mechanism with existing grid station

- Conducting and preparing report on preliminary environmental review of the project.

- Budgeting estimation of Capital costs for installation of a 35-50 MW biomass-fired power generation plant

EU SWITCH Asia High Pressure Cogeneration Capacity Building Project in the Sugar Sector

The European Union (EU) is funding an IHT (sister concern of PITCO) implemented High Pressure Cogeneration Capacity Building Project under SWITCH Asia Program. The specific objective of the project is to promote sustainable production of electricity through replication of high pressure cogeneration technologies in the sugar sector by supporting sugar mills through technology standardization, enabling access to finance, and mobilizing relevant public sector authorities.The project aims to achieve following results,

- Reduce environmental and social cost of production through increased use of high pressure cogeneration technologies by sugar mills; using saved bagasse for electricity generation & grid export (which is primarily fossil fuel based) resulting in a reduction of GHG emissions

- Replicate existing high pressure cogeneration practices by improving the capacity of 3 to 5 technology providers and 85 Sugar Mills (SMEs);creating linkages between 85 SMEs and 5 financiers; increasing the total share of SMEs with high pressure cogeneration implemented.

- Promote an improved policy framework for high pressure cogeneration technology with an attractive tariff and standardized regulatory procedures for bagasse based grid export of electricity.

Following activities are being implemented under the project:

Training and Capacity Building of the Sugar Sector and Technology Providers

- Establishment of a National Bagasse Power Support Cell at the PSMA, to offer technical, financial and regulatory assistance to its members

- Development of standardized technical specifications based on regional best practices for high pressure equipment design and operation, and preparation of project implementation tender documents based on consultation among technology providers and sugar mills

- In-house trainings and capacity building of Technology Providers to develop standardized HPC technology solutions

- Training of technical staff of sugar mills on standardized design and technology selection

- Development of business cases of technology switch to HPC for 70 sugar mills

- B2B linkages between local and Indian technology providers of HPC systems

Improving Access to Finance

- Financial risk assessment of bagasse based power projects

- Development of toolkits for SBP’s Schemes for Financing Power Plants Using Renewable Power, and the Credit Guarantee

- Trainings of the 5 major FIs in Pakistan on bagasse based co-generation projects and developed toolkits

- Training of sugar mill financial departments on toolkits and CDM

- Ensuring financial closure for 10 HPC projects

- Development of project design document for CDM financing for 10 projects

Development of a Conducive Regulatory Regime

- Establishment of Multi-stakeholder platform for bagasse based power systems

- Orientation of NEPRA on regional Best Practices of tariff determination for bagasse power projects, especially India, through regional stakeholder consultations

- Development of Cost of Power Generation study for bagasse based projects

- Development of toolkit for swift tariff determination and approval for bagasse based projects

- Conduct policy advocacy among Sugar Sector stakeholders, NEPRA, and the DISCOs

- Conducting Multi-stakeholder consultations on the adoption of a New Power Purchase Policy

- Revision of power purchase tariff for bagasse power

The project is being implemented by IHT (Lead Partner) which is sister concern of PITCO Private Limited, sequa GmbH Germany, The Energy and Resource Institute (TERI) India and Pakistan Sugar Mills Association (PSMA) Pakistan.

EU TRTA III: Pakistan Leather Competitiveness Improvement Program (PLCIP)

Pakistan’s leather industry represents 6.5% of Pakistan’s total export base. However, analysis of the value chain points out that Pakistani leather sector is skewed towards low value addition products. This focus towards low value addition markets is due to the low competitiveness of Pakistan Leather Product (LP) sector. Facing major challenges from China, India and Turkey, the Pakistan leather product sector must improve its competitiveness to increase exports. The way to improve the leather sector is to develop demand-driven business development services (BDS) to upgrade existing and future firms in the sector. The delivery of BDS is a transfer of innovation to organization (management, value chain, quality control, maintenance, and technical service), hardware (machines, tools and systems) and knowledge (information, experience, skills, attitudes, initial and further training) in the form of processes or products. SMEs in the leather sectors have to be convinced that the consumption of these BDS will bring them a real benefit.

The European Union is funding the PITCO implemented Pakistan Leather Competitiveness Improvement Program (PLCIP) under the Trade Related Technical Assistance (TRTA) Phase III. PLCIP aims to directly support the GoP trade policy by working along the value chain of the leather products sector in fostering export diversification and the promotion of the leather sector, leading to improved trade competitiveness and enhanced earnings for the country.

The objectives of the Program are:

- Improve the availability of demand-driven business development services (BDS) for leather product SMEs,

- Contribute to the competitiveness of the Pakistani leather sector

- Improve international market access of Pakistani leather products

Following activities are being implemented under the Program:

- Establishment and Operation of TRTA Competitiveness Cell (LCC)

PITCO is building the capacity of major leather sector associations i.e. Pakistan Leather Garments Manufacturer and Exporters Association – PLGMEA , Pakistan Gloves Manufacturers and Exporters Association- PGMEA, Pakistan Footwear Manufacturers Association –PFMA and Pakistan Tanners Association – PTA to act as lobbying organizations and providers of information services to the sector. Further it is assisting the associations in developing the agenda for “Leather Export Promotion Council” under the Federal Ministry of Commerce.

- Competitiveness Need Assessment of the Leather Product Sector

Detailed Competitiveness Need Assessment (CNA) of LP sector (Leather Garments, Leather Gloves and Leather Footwear) has been undertaken to identify key intervention areas for PLCIP in the technical and managerial practices of LP Sector in Pakistan. CNA was based on extensive secondary data research, primary survey of representative sample, walk through audit and presentation of the findings to the respective associations. CNA was led by international experts from International Shoe Competitiveness Centre and British Leather Centre.

- Capacity Building of the Business Development Services/ VET providers

SWOT analysis of BDS/VET providers was undertaken and matchmaking with the LP sector needs was done PLCIP has engaged international master trainers for the training of local BDS/VET providers based on the findings of CNA. These international master trainers are developing targeted training programs to facilitate knowledge transfer to local BDS/VET providers. These international experts will spend most of their time in Pakistan for Training of Trainers (ToT) and in particular the training of Pakistani master trainers. Training of trainers will involve extensive shop floor implementation of the VET and BDS under supervision of international experts.

- Marketing of BDS / VET providers via Showcases and trial audits and trial trainings

PLCIP is proposing ToT in such manner that it incorporates implementation of BDS/VET at shop floor hence the implementation of ToT will automatically transform into pilot demonstrations of improved BDS/VET. It is expected that 50 pilot projects will be undertaken in 30~40 showcased companies. Wide dissemination of the results of pilots will result in overcoming the resistance of change in LP firms.

- International Marketing Campaign for Leather Product Sector

Show cased LP Firms LP firms with high potential for export will be promoted with export plans, initiatives for branding, marketing, improved compliance, participation in trade fairs, CSR initiative as marketing tool, quality and productivity audits and linkages with trend makers and design institutes.

EU SWITCH Asia Project Sustainable and Cleaner Production in the Manufacturing Industries of Pakistan (SCI-Pak)

The project aims to develop a model for Sustainable Production through the implementation of a range of energy efficiency and resource recovery initiatives in the Textile and Tannery sectors in Pakistan, with the potential to adapt these initiatives to other manufacturing industries in the long-term (e.g. sugar, pulp & paper, steel re-rolling, etc.). The initiative covers following activities:

- Life Cycle Analysis of textile and leather processing industries

- Capacity Assessment of local industrial equipment manufacturers for technology transfer

- Transfer of Technology of Energy and resource Efficiency equipment manufacturing to local IEMs and Universities

- Implementation of Energy Efficient Pilot Initiatives along the entire production chain

- Development of Business cases for energy and resource efficiency initiatives

- Creation of a sustainable production network

- Creation of an Enabling Environment

- Policy Dialogue & Dissemination

More information is available about the project at www.sci-pak.org

The project is being implemented by the UNEP Center for Sustainable Consumption and Production at Wuppertal Institute (Germany), TTZ Bremerhaven (Germany), and PITCO’s sister concern IHT Pakistan, along with CPI Pakistan.

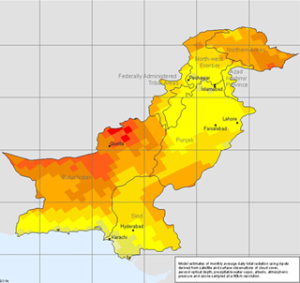

Feasibility Study of Biomass Power Generation for Government of Punjab

- Assessment of supply of the biomass fuel, its quantity & supply chain

- Evaluation and recommendations on specifications & size of the cutting edge technology, machinery, technology manufacturers, and installation & operation on sustainable basis

- Services include:

- Determination of biomass availability (location and seasonal variations) and present consumption of different biomass resources

- Comprehensive assessment of biomass value chain including, distances to the pilot power generation plants; transportation routes and costs; and role of farmers, biomass suppliers, and distributors

- Determination of most appropriate method and associated costs for preparation of biomass to facilitate transportation and utilization

- Comparative analysis of different technology applications for identification of most suitable power generation technology

- Detailed techno-economic analysis of the recommended technology including sensitivity analysis

- Recommendations on best mode of operation of the proposed power plants such as IPP, JV or public sector under PPP

- Analysis of relevant legal laws, regulations, issues and legal perspective

- Identification of risks associated with inception; Site/Location selection; overlapping jurisdiction; financial closure, operational, commercial, regulatory, political, force majeure and preparation of mitigation plan

CDKN Nationally Appropriate Mitigation Actions (NAMA) Project

Renewable Energy NAMA Sialkot, Pakistan (Phase-I)

Services provided:

- Map and assess the national and provincial policy and institutional environment governing industrial energy, and renewable energy (RE) deployment especially in Punjab as well as the current and future energy requirements, to determine the scope of necessary intervention

- Assess the range and viability (market and technological) for RE in the industrial sector in Sialkot, Punjab, and identify options that could be packaged into a NAMA

- Assess GHG emissions reduction potential of the options identified

- Assess the resilience and vulnerability of options to current and future projected climate change

- Estimate costs involved in implementing these options, including technical and financial risk profile of the action.

- Evaluate co-benefits (in terms of meeting other development objectives like environmental safeguards, improving energy security, climate resilience, jobs creation etc.)

- Analyse the barriers to implementation of identified mitigation options

- Estimate the time required before results can be realized in terms of GHG reduction and other goals like extra jobs created, cost reduction, etc.

- Analyse whether a NAMA is the most appropriate policy instrument for promoting renewable energy provision in the Punjab given technical and institutional capacities as well as other factors.

- Prioritize and list viable option/s that can be developed into a NAMA proposal or other policy instrument as appropriate, and map next steps in that direction, including resource requirements, envisioned outputs and outcomes, and timelines.

- Assess and engage the variety of stakeholders involved

- Conduct partners dialogue and consultations in order to determine/establish buy-in of the proposed idea and validate findings.

The Project is being implemented by Ecofys Germany, and PITCO is the local partner.

Supporting the Development of a Renewable Energy Solutions NAMA for Sialkot Industrial Sector and Climate Finance Access (Phase – II)

This project builds on the work delivered in a previous phase (NAMA Phase 1) of the project and aims to provide the government with a viable approach for planning and designing a practical support package for renewable energy in the Sialkot industry, including options for financing, structuring and implementation. The NAMA instrument provides a framework for this analysis, and potentially a viable option for the government to pursue. The project is intended to develop the basic engineering and financial scheme for a program that aims to install roof-top PV panels in hundreds of small and medium size enterprises in Sialkot. The objectives of this project are to:

- Develop the NAMA instrument for roof-top PV panels for Sialkot SMEs, specifically to provide a reliable source of energy to the Sialkot industry including the private sector

- Increase information and awareness of Sialkot Private Sector in climate finance opportunities such as GCF for possible NAMA co-financed implementation options

Services provided:

- Gap analysis in current policy and institutional framework with regards to the successful deployment of PV panels in Sialkot’s leather, sports and surgical sectors.

- Technical assessment, basic engineering on the estimated electricity generation on selected sites for estimates for the three industrial sectors. Includes baselines and cost-benefit analysis

- Financial analysis, estimates on potential costs and cash flows (cost savings) from the implementation of roof-top PV panels in the three industries based on the technical assessment

- Local Workshop on preliminary results

- Climate finance component: Climate finance/ GCF Awareness raising/access modalities/ institutional analysis/ recommendation Report

- MRV system and protocol for the sites with a finalized technical and financial analysis that best fit the capacities and resources of the Pakistani government

- Tentative NAMA implementation plan with tasks, key indicators (outputs and outcomes), timeline and the roles and responsibilities

- Climate Finance Recommendation Report .

- National workshop for the official presentation of the proposed NAMA Report.

World Bank Capacity Building for Energy Efficiency in Punjab

Project is mainly focused on capacity building of Energy Department Punjab for implementing the Energy Efficiency & Conservation Strategy devised earlier. The duration of the project is . International Finance Corporation (IFC), the World Bank Group, is supporting the implementation of the strategy through Korea Energy Agency (KEA), Ernst & Young (EY) Korea, EY Pakistan and PITCO Private Limited Pakistan.

PITCO has lead role in two components of the project:

- In-depth Regulatory and Institutional Analysis